Cybersecurity in Manufacturing: Top Cyber Threats For Manufacturers

By

Jason Miller

·

10 minute read

By

Jason Miller

·

10 minute read

Cybersecurity is making headlines in many industries regularly. Last year's high-profile SolarWinds attack and the recent Colonial Pipeline hack have government officials scrambling to implement new regulations that create effective cybersecurity solutions. Companies across the education sector, financial sector, and even the utility industry are making vital changes to avoid becoming a target for major threat actors. However, one industry facing high cybersecurity risks has a lot of catching up to do. Historically, manufacturing companies have been comfortable in the misinformed theory they aren't a target for hackers. After all, insurance companies and financial institutions are the types of organizations that handle millions of dollars. This leads manufacturing companies to the false idea they do not require strong cybersecurity.

Similar to physical crimes, cyber crimes aren't singularly focused on cold, hard cash. Instead, hackers focus on the potential value of the data they could access through a breach. This could be personal information, government information, intellectual property, or operational information owned by the company. Simply put, manufacturing companies have data with considerable value to hackers. Even worse, the lack of preparation in this industry makes these companies an easy target. As financial companies and government organizations are using more advanced cybersecurity to comply with new regulations, hackers are looking in a new direction. Manufacturing companies without cybersecurity have a combination of value and accessibility that makes them the perfect target.

According to IBM data, the manufacturing sector moved from the 8th most targeted industry in 2019 to number 2 in 2020, following only finance and insurance. Unfortunately, for companies already affected, the lesson in the need for enhanced cybersecurity has been an expensive one. Ransomware is the most common type of attack in the industry, forcing companies to pay hundreds of thousands in ransom payments or face the (often more expensive) cost of replacement and repair of devices or entire networks. Unfortunately, the cost of cybercrime continues to grow, predicted to result in damages that top $6 trillion, globally, in 2021. Without intervention, this spells bad news for manufacturing companies.

Top Cyber Threats for Manufacturers

As with many industries, the majority of employees within manufacturing companies are largely unaware of the likelihood of a cyberattack and how to avoid it. This makes companies vulnerable to attacks that prey on employees and create breaches that wouldn't otherwise exist in the network. Understanding the potential threats and educating employees is the first step in practicing cybersecurity hygiene. These are the most common cybersecurity threats manufacturing companies face.

Theft of Sensitive InformationWhen threat actors gain access to a network, they often move within the system to gain access to multiple points of interest. If you've ever experienced the fear that comes with a large purchase on your credit card you didn't make or the sudden disappearance of cash from your checking account, you know the dangers of failing to protect your personal information. As a company responsible for sensitive data linked to thousands of people, the dangers are even more ominous. Hackers can gain access to a network and discreetly move through the system until they reach the sensitive personal information of thousands of customers.

For your customers, this can mean stolen card numbers leading to a hassle with the bank. Even worse, stolen social security numbers can lead to outright identity theft that can affect individuals for years. For the responsible company, the publicity alone can destroy public trust. Since all companies that collect personal data are required to protect that data, expensive fines and lawsuits can follow. Some companies never recover from a major data breach.

Phishing and Spear Phishing

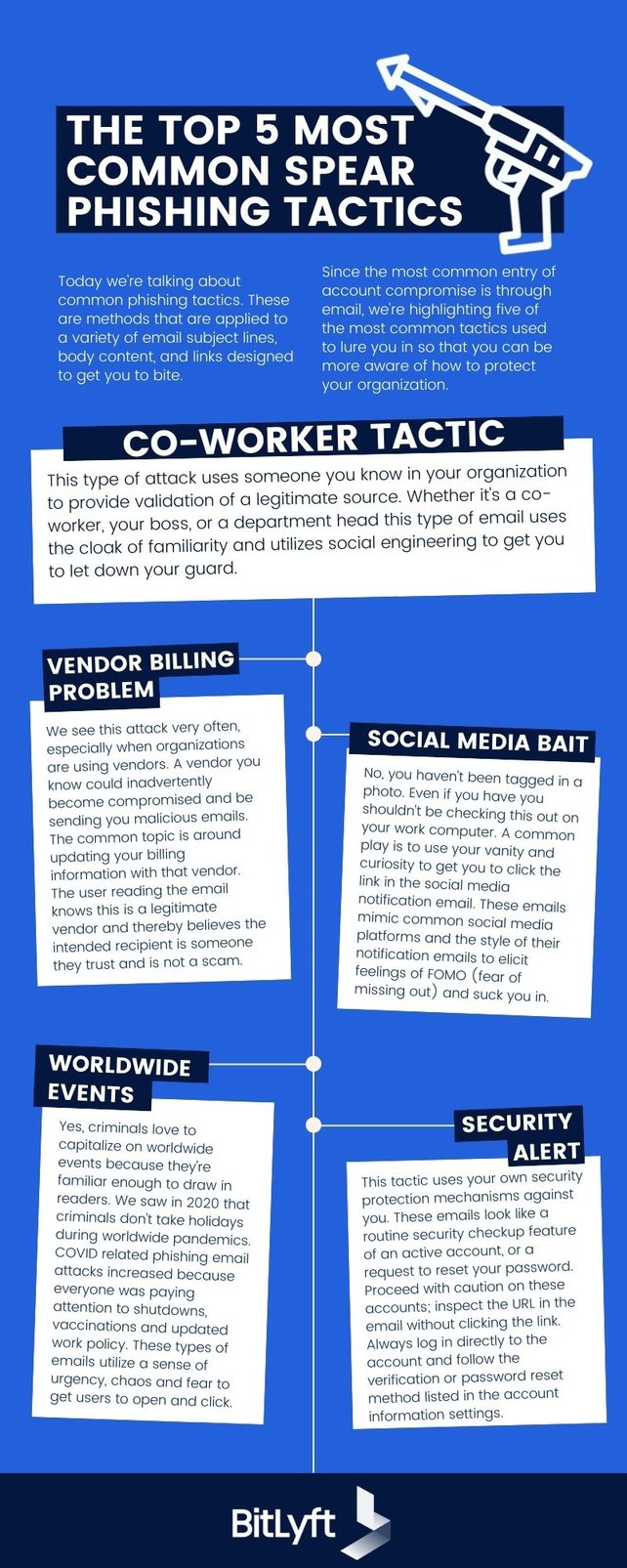

Phishing is one of the most common ways hackers attempt to gain access to a system. It's so common many computer users are aware of the threat and what to avoid. For instance, you wouldn't likely be fooled by a letter addressed to "Dear Valued Customer," or "Dear Respected Employee," but some phishing attempts are more difficult to ignore. A letter that includes the company logo of one of your vendors and includes your name (although vendors may be listed on the company website and your name is part of your email address) feels more genuine.

Spear phishing takes this practice to another level by targeting specific employees and using communication methods that appear to come from within the company. Spear phishing attempts are usually highly specific and refer to individual order, event, or account in an attempt to appear legitimate. These communications generally ask for more information, passwords, or codes that would provide hackers with access that would otherwise be restricted.

Ransomware

Like most industries, companies in the manufacturing sector face tight deadlines and a busy schedule. For these companies time is money, and hackers know the cost of downtime for an organization. Hackers deploy ransomware into a company's network that encrypts files, making the system useless to the company. For organizations that mass produce products, downtime is a serious threat to success. Even worse, interconnected industries depending on these products will quickly become affected as well, producing a ripple effect. Hackers take advantage of this knowledge by demanding hundreds of thousands of dollars for the decryption of affected software in a short period. Unfortunately, meeting the demands of such threat actors doesn't always pay off, and companies are still forced to deal with the costs and lengthy repair time of getting the system back on track.

Spam

While ignoring spam on your device is usually fairly easy, hackers can utilize useless information to distract employees within a company and desensitize individuals to real threats as they arise. Hackers send companies an avalanche of spam mail with characteristics that allow these communications to pass through traditional spam filters, resulting in tedious hours spent by employees to manually sort messages. These actions limit production and distract employees from real threats on the horizon.

False Web Pages

Whether you're at work or home, as a computer user, you learn to depend on certain sources as legitimate websites or organizations. Threat actors can exploit this dependence by creating compromised web pages that closely resemble the ones your customers already use. When hackers access the network of a company, they often move laterally through the system to gain access to a variety of potential assets. Your company's website can be one of these assets. After gaining access, hackers make web pages inoperable or even automatically install dangerous files on the devices of those who visit the site. These occurrences can result in irreparable damage to the reputation of your company.

Supply Chain Attacks

More than ever before, manufacturing companies communicate information to a variety of endpoints. Manufacturing companies with or without cybersecurity depend on partners, vendors, shipping companies, investors, and storage facilities to keep everyday operations running smoothly. These third parties have access to certain information or can serve as an entry point for hackers to access your network. Known as a third-party attack, hackers use the vulnerability of connected parties to gain access to a company or organization. The recent SolarWinds attack has highlighted the dangers of such attacks and the need for companies in all industries to protect against them.

Changing Technology Increases Access for Threat Actors

Along with the lack of preparedness in the manufacturing industry comes a quickly changing landscape of advanced equipment and systems that are revolutionizing the entire sector. While these advancements improve many aspects of manufacturing to make processes easier, they also create more points of vulnerability for hackers to exploit.

Industry 4.0 Brings Benefits and Risks

Whether you believe the fourth industrial revolution is a major advancement in technology or think it's an advertising buzzword, there's no doubt that an expansion in technology and interconnected devices and systems exist. Utilizing these advancements requires responsible implementation and the use of more advanced cybersecurity techniques. From a manufacturing point of view, Industry 4.0 streamlines processes with the interconnection of information technology (IT) and operational technology (OT). This expanded landscape brings new points of vulnerability and a variety of ways for hackers to target manufacturers. The main components of Industry 4.0 that affect the manufacturing industry include:

- Internet of Things: The internet of things (IoT) and the industrial internet of things (IIoT) refers to objects embedded with the technology to communicate with devices across the internet.

- Machine to Machine Communication (M2M): Similar to IoT, M2M allows machines to communicate with one another or computers without human intervention.

- Increased Reliance on the Cloud: The ability to provide real-time information is essential for keeping up with the changing nature of the manufacturing industry and related supply chains. Utilizing IoT devices and M2M communication naturally leads to increased reliance on the cloud as well.

- 3D Printing: While still in the early stages of becoming widely utilized, the potential for 3D printing to be commonplace in the manufacturing industry seems likely.

Why These Advancements Bring About New Threats

Along with the increasing communication surface provided by new technologies comes an expanded attack surface for hackers to exploit. The use of the IoT and M2M combine to form advanced operational technology that can allow humans to complete tasks faster and more efficiently than ever before, but each of these devices represents a point of potential vulnerability. Consider these cybersecurity risks brought about by industry 4.0.

- Increased communication between devices provides more points of vulnerability for hackers to exploit.

- Mass-produced IoT devices with the same factory settings can be easily accessed by hackers when companies fail to take time to change passwords. ● Gaining visibility across an entire IT/OT connected system is difficult. ● IoT and M2M devices are designed to work without human intervention, making them vulnerable to discreet attacks.

- Upgrades are often not unified, leaving potential gaps in security. ● Covert attacks have the potential to target smart devices and machines and change the way they complete projects, leading to flawed or dangerous products.

The IoT Cybersecurity Improvement Act is a step in the right direction to help tackle the cybersecurity threats brought about by the use of new technology in manufacturing, but more changes will be required for a complete and broad-reaching solution.

CMMC and Manufacturing

If you're one of the manufacturing companies with cybersecurity that work on contracts from the DoD, you likely have some knowledge of the importance of the CMMC. However, many organizations fail to understand the relation between CMMC and the manufacturing sector. The CMMC, or Cybersecurity Maturity Model Certification, is a certification procedure developed by the Department of Defense to certify that contractors working with the department have the necessary controls to protect sensitive data. While the protection of government data seems irrelevant to manufacturing, many companies use government information for the completion of contracted projects. Additionally, as the standards are implemented successfully, more companies and organizations may require CMMC compliance in the future.

CMMC standards will soon apply to all manufacturing companies and suppliers who sell to the U.S. Department of Defense (DoD). This means if you win contracts for DoD or supply parts to a company for a DoD contracted project, you'll be required to achieve some level of compliance. If you're a company that regularly wins contracts with the DoD, it's essential to evaluate your CMMC readiness early in the game. While the phased rollout isn't scheduled to be complete until September 2025, some new contracts will be affected as early as this year. Getting started early with the requirements to obtain CMMC compliance will be key for some companies that aren't currently practicing NIST standards.

While the benefits of CMMC compliance are clear, understanding the consequences of failing to meet minimum standards might be even more important. Manufacturing companies that require CMMC compliance and fail to correctly implement the standards could face these consequences.

- The inability to bid on DoD contracts

- Penalties and fines related to noncompliance

- The potential to get replaced by other companies that are properly prepared ● Potential delays 3PAO certification schedules can mean you won't be prepared for contract renewal for your existing DoD contracts

The Dangers of Postponing Cybersecurity in Manufacturing

As the landscape of manufacturing is changing, it can be easy to skip steps and focus on the big picture. Small and medium businesses often think they have a lower risk factor than major corporations and multi-million dollar organizations. Unfortunately, this kind of thinking could make you a more attractive target for threat actors seeking an easily accessible network. Medium and small businesses can provide easier access to hackers and could be an even more likely target than major corporations. Consider these dangers of delaying an effective cybersecurity plan for your manufacturing company.

Delayed Progress within Your Company

Innovation and growth drive the manufacturing industry. In an ever-changing landscape where products are constantly meeting new challenges and being produced more efficiently than ever before, your company can't afford to stay in the past. Yet, moving forward with technology that poses new risks can be a dangerous move if you don't have the right security measures in place. Since advancements should come along with the security measures that protect them, delaying cybersecurity could mean delaying company growth as your competitors put themselves in a position to attract your customers.

Lost Contracts

As cyberattacks grow in scope and severity, government officials are taking notice. Threat actors are getting bolder, demanding higher ransoms, and launching attacks that have a serious impact on the infrastructure of the nation. As these threats expand to impact major utilities and government organizations, new regulations are passed to create safer networks that protect consumers and the security of states and the nation as a whole. For manufacturing companies that fail to implement the required cybersecurity standards, valuable contracts could be lost.

Increased Vulnerability to Attacks

As companies in the manufacturing sector get an understanding of the potential for increased cyber threats within the industry, many will adopt security programs to mitigate the risk. Additionally, many companies will be eager to tackle the task of meeting compliance regulations outlined by CMMC and the IoT Cybersecurity Act before they fall behind. Failing to keep up makes your company a target simply because the network is more accessible than those of comparable companies.

Penalties and Fees for Non-compliance

Whether you bid on contracts for the DoD or other government organizations or not, you're responsible for sensitive data that you gather and store. There are a variety of regulations that exist to enforce the responsibilities of companies and organizations

regarding customer information. Within the manufacturing sector, these requirements may be derived from GDPR, the Federal Trade Commission Act, COPPA, HIPAA, or the Fair Credit Reporting Act. Newer regulations like CMMC and those outlined in the IoT Cybersecurity Improvement Act will be included soon as well. If you fail to follow the requirements that apply to your company costly fees and penalties will follow.

The Ripple Effect

Mass production in manufacturing is one of the most efficient ways to produce products used by millions of people each day. If your company stops production due to a cyberattack, every member of the supply chain beyond your company is affected. Consider manufacturing companies that produce electrical panels for a variety of products, or an organization that produces a specific healthcare product used in hospitals. When one of these companies experiences downtime, the companies that depend on these products are quickly affected as well. If threat actors generate a stealthy attack that compromises these products, consumer injuries could result.

How to Evaluate Your Cybersecurity Risks and Create an Effective Solution

Whether you're attempting to meet standards outlined by government regulations or hoping to prevent the likelihood of an attack within your organization, learning your current position will help you determine the measures you need to take to achieve adequate cybersecurity practices. A comprehensive plan that provides relevant software and educates employees can help you protect your company. Take these steps to protect your manufacturing company from growing cyberattacks.

Assess Your Risk

Standards outlined by NIST guidelines and used in the first two levels of CMMC outline basic cybersecurity practices that should be used by all companies. Learning these standards and determining how close your company comes to meeting them is a good way to assess cyber readiness.

Educate Employees

Lack of awareness is a major contributor to vulnerabilities within any company. Taking the time to inform employees of the potential risks and educating all levels of employees about how to avoid these risks can strengthen your company's security. Your security plan should be a document that outlines security practices, provides a plan of action for security breaches and includes steps to remediate threats.

Inventory Devices

Connected devices serve as vulnerability points into your company's network. Keeping an updated inventory of all devices and the defenses used for each device will help keep your cybersecurity up to date. Your inventory should include any patches or updates applied to each device.

Invest In a Professional Solution

For many small to medium businesses, an in-house cybersecurity team isn't an affordable option. Hiring a third-party cybersecurity company is often a solution that provides the same type of protection. Advanced and automated solutions for threat detection and remediation provide visibility into your company's network to provide alerts to threats before they cause damage. Cybersecurity solutions from BitLyft combine security information and event management (SIEM), automated responses to incidents, alerts, and threats (SOAR), and a central threat intelligence that provides crowdsourced immunization for attacks that haven't reached your company. Third-party cybersecurity companies can help manufacturing companies with cybersecurity and perform a gap assessment, take steps to achieve necessary compliance, and avoid potential attacks.

Assuming that your manufacturing company is too small or unimportant to attract cybercriminals makes you a prime target for attack. Failing to keep up with necessary security measures will result in distrust and a lack of confidence in your company. Cybersecurity in the age of Industry 4.0 is an essential part of manufacturing. Getting started right away will prevent you from falling behind. To learn more about cybersecurity for manufacturing companies and the steps you can take to protect your company, talk to the cybersecurity experts at BitLyft today.